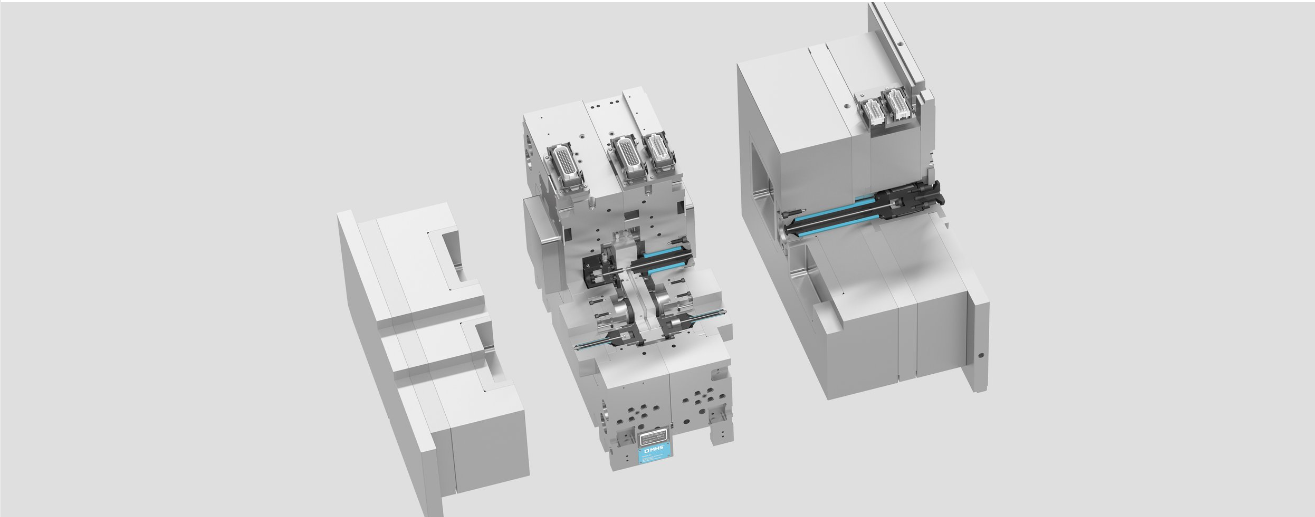

Aboult ANOLE

Hot runner system can increase production efficiency, save plastic material and reduce cycle time of injection molding. It is widely used in developed countries and more and more popular in developed countries.

The hot runner system is developed and widely used because of the following reasons:

Energy crisis

The rapid development of hot runner is on 1973, when the oil crisis happened. Most plastic molding manufacturer tends to use hot runner system to plastic raw material and reduce the most. The hot runner is the new technology correspond with the demand of high production,low cost and economical.

Higher quality demand of injection products

For plastic injection medical products, the injection mark may scarify the groove and skin of health care staff and get infection. Using valve gate hot runner system can eliminate injection mark. For some high class product just like transparent product, cold runner and recycled material are not permitted, it must use hot runner system reduce the use of plastic raw material.

The special requirement of injection technology

Co-injection means that through reasonable design of mould, the plastic product can reach many colors. Or use two kind of plastic material to make one product. Also, stack molding, and preform mould will need hot runner system.